With unprecedented change and upheaval in the automotive supply chain, improving the resilience of your operation has never been more important and we highlight how returnable plastic packaging can help you mitigate the risks.

A combination of the global pandemic, changing political headwinds, material shortages and rising costs has resulted in OEMs and Tier Suppliers having to rapidly adapt how and where they source and ship component parts. The need for change has highlighted how the automotive supply chain can innovate to meet today’s challenges but also evolve to make long term improvements.

We have taken a deep look at how returnable plastic packaging can help you make these changes –

Costs savings at each stage – inbound and outbound

The significant increase in fuel and shipping costs across the globe has focused the attention of automotive OEMs and Tier Suppliers to identify opportunities to reduce costs in their supply chain.

We are now seeing proven statistics and data from the Global Logistics Emissions Council (GLEC) who are working closely with OEMs to accurately calculate and report on the emissions generated in the supply chain to identify cost savings.

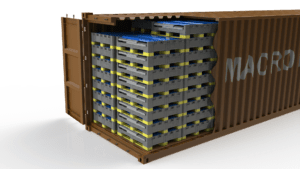

Introducing returnable plastic packaging and creating returnable loops will improve space utilisation in all forms of transport and containers, helping you to ship more for less.

Increasing your pack density will reduce the number of journeys and fuel required in your supply chain, helping you cut costs and reap the environmental benefits.

Replacing single use, expendable packaging with returnable plastic packaging removes the cost of repurchasing packaging and disposing of waste after use which has been heightened in recent times as the cost of manufacturing single use packaging has increased. For example, there was a shortage of corrugated cardboard across the globe as paper mills were shut due to the pandemic, resulting in significant prices increases for a material that was going to be used once.

Transitioning to an easily stackable returnable solution will provide you with cost down opportunities when being shipped empty and stored in comparison to rigid metal stillages.

Future proofing your packaging – shift to EV, environmental laws and fines, market disruption

Considering introducing returnable plastic packaging now will future proof your supply chain, especially with the rapid introduction of new EV models.

With new laws and risk of potential fines in relation to sustainability and generating carbon emissions, it is only a matter of time before expendable and heavy weight packaging becomes unviable. Rigid plastic folding bins such as the IPL Macro EuroBin will help you to reduce the number of trips required in your supply chain. The associated fuel and emission savings will ensure that you are compliant with environmental legislation.

Using a returnable plastic bin that you own or rent limits your risk to market disruption in relation to sourcing single-use packaging. Once you have purchased or leased plastic bins, they are in your logistic loops. You aren’t at risk of not being able to purchase or take delivery of expendable packaging throughout the lifetime of a vehicle.

Reduced maintenance costs and time savings

In comparison to other returnable packaging solutions, the EuroBin has been designed with the ease of maintenance and repair in mind. With easily replaceable parts like forkstraps and folding doors, which are most at risk of damage, repairs can be done in the plant by the OEM or Tier Supplier.

This minimises the time bins spend out of the supply chain, helping to maintain the number of bins use in the supply chain, reducing the need to purchase replacements or experience a shortage. With low-cost and easily replaceable parts, you are able to prolong the lifespan of a bin to last a vehicle lifecycle.

Sustainable solution – Fully Recyclable

Plastic returnable bins help OEMs and Tier Suppliers improve the sustainability of the supply chain and logistics operations at every stage and touch point, from Tier Supplier, transportation, handling, outbound and end-of-life. They are designed to continually help drive efficiencies every time it is used for its entire lifecycle.

Reduce fuel consumption, remove trailers from the supply chain, and limit waste disposal with plastic returnable bins. Using 100% virgin polypropylene means the EuroBin is fully recyclable at the end of life. This reduces waste from the automotive supply whilst also presenting the opportunity to reclaim part of the cost of each bin when recycled, and to use the recycled materials for future manufacturing.