The MacroTote 5-FV is a lightweight single-piece folding tote with a living hinge folding system that allows it to be collapsed and stacked with a 5:1 return ratio. Designed for harvesting, storage and distribution of produce with multiple vent holes and a 1” drop on the top of the sidewall for quick cool down and easy viewing of the contents. The purpose of this guide is to review all aspects for the safe use of the MacroTote 5-FV.

Table of Contents

Set Up Process

Collapse Process

Transporting

Empty Storage/Collapse Return

Field Handling

Maintenance

Cleaning

Recycling

- Place the flat collapsed and folded 5-FV bin on a flat surface.

- Raise the long sidewalls until vertical.

- Rotate the short endwalls to the point where the latch extensions line up with the openings in the upper corners of the endwalls.

- Push the endwalls in until the latches click and lock into the endwalls.

- Repeat at the opposite end.

- The tote is now ready for filling.

MacroTote 5-FV Collapse Process

- Place erect empty bin on a flat surface.

- On the end walls, place fingers into the openings on the corner post next to the latch on both sides.

- Push in the lathes while pulling out the endwall until it disengages from the sidewall.

- Repeat with opposite endwall.

- Fold the sidewalls in on top of the tote floor.

- Lift the tote so the endwalls can be fully rotated under the bottom of the tote.

- Rotate the endwalls so they are under the tote floor.

- The collapsed and folded tote can now be stacked on other collapsed and folded totes.

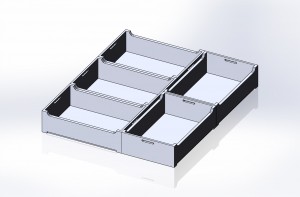

The MacroTote 5-FV was designed for one way transport of produce 5 down, 10 high on 1000 mm x 1200 mm standard pallet. The stacking configuration is illustrated below. When stacking full totes on pallets, it is important to position the tote corners to line up with slats on the pallet. Positioning the corners over the spaces between the slats could result in deformation to the totes.

Full totes are stacked 10 high on pallets in the field. 10 high sacks are secured to the pallet using vertical cardboard corner braces along the corners of the pallet. Corner braces should run from the ground, up the full height of the staked bins to secure the stack to the pallet. 3 or 4 horizontal straps should be used to secure the corner braces at the middle of the block and at the top and bottom of the stack. The photos below illustrate this stacking system:

The full pallets can be stacked 2 pallets high in cold storage while awaiting refrigerated trailers to transport produce to customers. When placed in refrigerated trailers, palletized stacks of totes must be secured to ensure they do not shift in transport. The fully vented bins ensure superior airflow to keep the contents cool throughout shipping.

Empty Storage / Collapsed Return

Empty totes can be stored 35 high on a pallet. They are stacked in the same configuration as the full erected totes and should be secured to the pallet in the same manner as full, erected totes.

The 5-FV is compatible with all current hand carts used to transport totes into and out of the field.

Cracks on the sidewalls can be repaired using a hot air welding system. Damage to the corner support sections cannot be repaired.

Totes can be cleaned using a high-pressure spray washer. High-pressure steam cleaners should never be used.

For information on recycling damaged or worn-out totes, visit http://www.macroplastics.com/services/recycling/.