The Hybrid 44 was developed as a more cost effective and customizable alternative to the traditional MacroBin. In addition to lowering initial shipping costs, efficiencies can be gained over the traditional nested transport to the field and storage at the packing house. The purpose of this guide is to review all aspects for the safe use of the Hybrid 44 Series bin.

Table of Contents

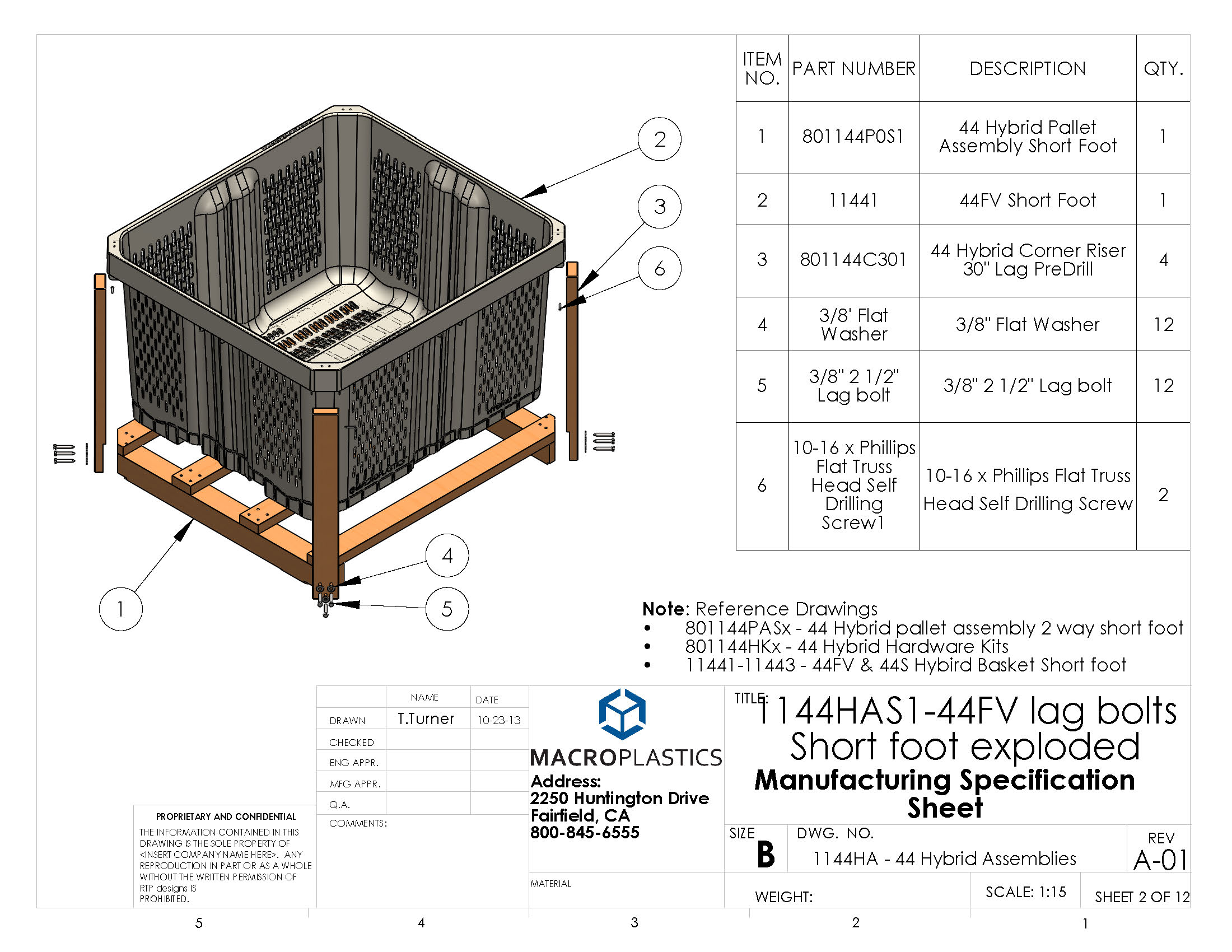

Component Parts – Risers Attached with Lag Bolts

Assembly Process

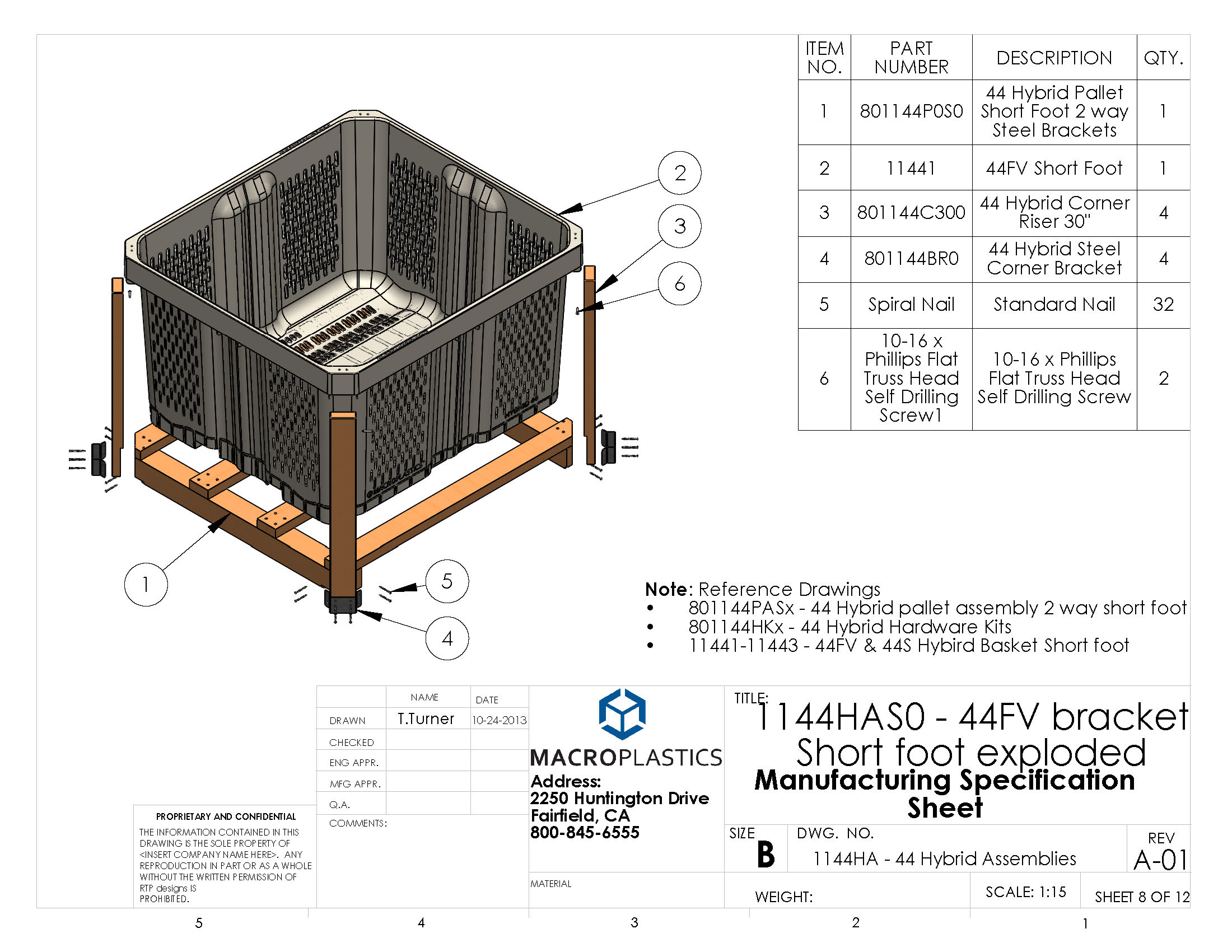

Component Parts – Riser Attached with Steel Bracket

Assembly Process

Safe Usage

Safe Handling Practices

Bin Transportation

Corner Irons and Cables

Flatbed Single and Double Trailers

Bin Movement – Forward / Back

Bin Movement – Side to Side

Bin Loading on Trailers

Straddle Lift Trailers

Pick-up Trucks and Small Trucks with Flatbeds

Storage

Maximum Capacity and Stack Weights

Interstacking

Handling Equipment

Forklift Handling

Bin Trailers

Motorized Bin Carriers

Packinghouse Equipment

Destackers

Dumpers

Stackers

Floaters

Pre-Sizing Lines

Cleaning

Maintenance

Recycling

Component Parts – Risers Attached with Lag Bolts

Assembly Process – Hybrid 44 with Corner Risers Attached with Lag Bolts

Hybrid 44 bins are shipped new with the plastic bin tubs nested together on the wood pallet bases and the wood pallet assembly parts loaded on the remaining pallet bases. Different wood types and pallet configurations can be ordered to customer specifications but all have the same basic design as the short foot version in the above drawings. The corner riser can be secured to the pallet using lag bolts or a steel bracket and nails.

Tools needed – 3/8 socket and socket wrench, Philips head screw driver

1. Place the pallet (Item # 1) on a level, flat surface.

2. Place the 44 Series plastic tub (Item # 2) squarely on the pallet so the ribs on the floor of the tub are nested over the ribs on the pallet and the corners are directly over the corners of the pallet.

3. Insert the top of the corner riser (Item # 3) into the corner pocket of the plastic tub.

4. Line up the 3 pre-drilled holes on the bottom of the riser, with the pre-drilled holes on the pallet corner.

5. Insert the flat washers (Item # 4) into the pre-drilled holes on the corner riser.

6. Line up the holes on the beveled end of the corner riser (Item # 3) with the holes on the corner of the pallet.

7. Using the socket wrench, screw in the 3 lag bolts (Item # 5) until tight.

8. Repeat for the remaining corner risers.

9. Screw a truss head screw (Item # 6) through opposite sides of the corner of the plastic tub (Item # 2) into the side of the corner riser (Item # 3) securing the plastic tub to the corner risers.

Component Parts – Riser Attached with Steel Bracket

Hybrid 44 Assembly Process – Riser Attached with Steel Bracket

Hybrid 44 Series MacroBins are shipped new with the plastic bin tubs nested together on the wood pallet bases and the wood pallet assembly parts loaded on the remaining pallet bases. Different wood types and pallet configurations can be ordered to customer specifications but all have the same basic design as the short foot version in the above drawings. The corner riser can be secured to the pallet using lag bolts or a steel bracket and nails.

Tools needed – Hammer, Clamp, Phillips Head Screw Driver

1. Place the pallet (Item # 1) on a level, flat surface.

2. Place the 44 Series plastic tub (Item # 2) squarely on the pallet so the ribs on the floor of the tub are nested over the ribs on the pallet and the corners are directly over the corners of the pallet.

3. Line up the steel bracket (Item # 4) with the bottom, beveled end of the corner riser (Item # 3).

4. Securely clamp the steel bracket to the bottom of the corner riser.

5. Hammer 4 of the spiral nails (Item # 5) through the pre-drilled holes on the steel bracket, securely attaching the steel bracket to the bottom of the corner riser.

6. Insert the top of the corner riser into the corner pocket of the plastic tub.

7. Line up corner riser flat against the corner of the pallet so the flanges on the steel bracket are flush with the pallet .

8. Hammer 4 of the spiral nails through the pre-drilled holes in the steel bracket flanges, securely attaching the bottom of the corner riser to the pallet.

9. Repeat for the remaining corner risers.

10. Screw a truss head screw (Item # 6) through opposite sides of the corner of the plastic tub (Item # 2) into the side of the corner riser (Item # 3) securing the plastic tub to the corner risers.

Safe Usage

The 44 Series Hybrid has been designed for the harvesting, transportation, and storage of fruit, vegetables,and other types of commodities. All 44 Series Hybrid tubs are molded from materials that have been tested and are in compliance with FDA guidelines for food contact.

The 44 Series Hybrid must be used in accordance with design specifications that are outlined on the product specification sheet. Product specification sheets are available from Macro Plastics’ Sales Representatives, the Technical Services Department, or online at www.macroplastics.com and should be fully reviewed before 44 Series Hybrid bins are used. The following must be observed:

- When storing materials other than agricultural commodities, when treating commodities stored in 44 Series Hybrid bins or when cleaning or sanitizing, the resistance of PP to degradation due to contact with these chemicals should be reviewed. This should be done by contacting your sales Representative, or the Customer Service Department. If there is any doubt as to the suitability of chemicals used on 44 Series Hybrid, testing should be completed to ensure the 44 Series Hybrid will not be damaged from long-term contact with the chemical in question.

- Heavy objects should not be dropped onto the floor of the bin as they could damage the bin floor.

- Holes should not be drilled in the bins as any modification to 44 Series Hybrid bins will void the warranty and may negatively impact the structural integrity of the bins.

- 44 Series Hybrid bins with damage to the corner post should be taken out of service and recycled.

- 44 Series Hybrid bin stacks must not be pushed over or off of trucks onto hard surfaces such as concrete.

- 44 Series Hybrid bins should be periodically inspected for structural damage to the corner posts and upper ribs. This is very important in applications where 44 Series Hybrid bins are stacked, as the corner posts bear most of the load. Any cuts or cracks that damage the interior support ribs of the corner posts may cause structural failure in a stack. 44 Series Hybrid bins found in this condition should be recycled.

Safe Handling Practices

Bins must be secured to the vehicle used for transport in a manner that eliminates bin movement while the vehicle is moving, even if only a single bin is involved. All bins should be forced together without space between them to form a unitized load. The U.S. Department of Transportation (DOT) does not currently have a commodity specific cargo securement technique for the transport of bins. To understand the most effective cargo securement techniques for the interstate transport of 44 Series Hybrid bins, the DOT – Federal Motor Carrier Safety Administration (FMCSA) has the Federal Motor Carrier Safety Regulations (FMCSRs) available on the FMCSA website at www.fmcsa.dot.gov. The general cargo securement requirements are listed under 49 CFR 393.100 – 393.114.

For intrastate travel, tie-down methods must comply with local regulations regarding bin hauling. It is the responsibility of the user to ensure they are in compliance with these regulations. Internet links to truck-related regulation web sites for all 50 states are listed in the index at the end of this User Guide. This information will be updated periodically at www.macroplastics.com. The U.S. Department of Transportation – Federal Motor Carrier Safety Administration (FMCSA) has the Federal Motor Carrier Safety Requirements available on the FMCSA website at www.fmcsa.dot.gov. The general cargo securement requirements are listed under 49 CFR 393.100 – 393.114. Some of the more widespread bin transportation methods are outlined in this section.

In many areas of the country, corner irons and cables are utilized in the transportation of empty bins or bins filled with agricultural produce. Due to the angled corners of 44 Series Hybrid bins, corner irons used to secure wood bins or traditional MacroBins, may not be as effective as a corner iron specifically designed for the 44 Series Hybrid bin corner post. To eliminate this problem, it is highly recommended that corner irons be used that satisfy the following guidelines:

- The corner iron sides must be at least 5” wide.

- The cable hook should be 12” to 24” from the top of the bin in use.

- The top hook should be designed to hook over the corner post.

Corner irons can be purchased from:

Local Utility Trailer Dealer – For the closest location go to www.utilitytrailer.com.

Flatbed Single or Double Trailers

44 Series Hybrid bins offer distinct advantages over wood bins when hauling on trailers due to the interlocking feature of the foot with the top of the top edge of the bin beneath it. This allows for proper positioning while stacking 44 Series Hybrid bins. The upper bin will not fall into the bin below and a more stable block is formed when corner irons and cables are used to contain the bins.

To minimize sliding issues when transporting 44 Series Hybrid bins, precautions should be taken to prevent bins from sliding forward or backward, as well as side-to-side.

Bin Movement – Forward/Backward

The force of the wind hitting the front stack of bins tends to force the load on a trailer to the rear. Also, depending on the locations of the winches and hooks, cables can force the block forward, back, or just inward and down. A sudden stop may cause the bins to slide forward. 49 CFR 393.102 of the FMCSA general cargo securement rules requires that any securement system prevent movement of the load in a 0.435g deceleration in the forward direction or a 0.5g deceleration in the rearward direction. To ensure that this is done, Macro Plastics recommends that all rows be secured with cargo securement devices meeting the requirements of 49 CFR 393.104 and 393.108 of the FMCSA general cargo securement requirements. In addition to using the proper cargo securement devices, the following points should be considered:

- Use trailers with front bulk heads.

- Weld angle irons tops to the front and rear of the trailer.

- If stake holes are present at the front and rear of the trailer, stakes can be placed in these holes.

Above options must all comply with the requirements of 49 CFR 393.104.

As double trailers are pulled down the highway, the rear trailer can sway from side to side creating the potential for side drift of bins. Hard corners and high winds further contribute to this problem, increasing the probability of side drift. The FMCSA cargo securement regulation 49 CFR 393.102 states that loads must be secured to prevent movement in 0.25g lateral acceleration. To ensure that this is done, Macro Plastics recommends that all rows be secured with cargo securement devices meeting the requirements of 49 CFR 393.104 and 393.108 of the FMCSA general cargo securement requirements. If winches are not present, suitable rope can be used.

See 49 CFR 393.108 in the FMCSA general cargo securement regulations.

- When loading 44 Series Hybrid bins onto trailers the following guidelines are recommended:

- On trailers without a headboard or other stops at the front and rear of the trailers, it is recommended that stakes be put in place before loading, if stake pockets are available. Stakes should be placed at both ends of each of the trailers and comply with 49 CFR 393.104.

- Load the bins starting at the bulkhead end of the trailer with the bins placed tight against the bulkhead, stakes, or stops. The bin stacks should be loaded tightly together to form a unitized block. It is important to pack the bins tightly together before corner irons and cables are put into place. This will require less force to be applied to the corner irons and cables to pull the bins together, as all bins must be touching when the tie-down is complete.

- After all bins are loaded, corner irons should be put into place so cables can be fitted. To help with fitting corner irons, provisions should be made to safely lift corner irons onto empty bin loads stacked four high. Corner irons, cables, clamps, as well as attachment and anchor points on trailers must be inspected before each use to ensure they are in good condition. See 49 CFR 393.104 of FMCSA Cargo Securement Rules.

- Cables should then be put in place and tightened.

- Cables are needed to securely hold down the load and force bins together tightly. Over-tightening the cables can cause deformation of the corner posts, so care must be taken when tightening cables.

- To ensure that the load is secure as possible, Macro Plastics recommends that each row of MacroBins be secured using straps which meet the requirements as specified in DOT Federal Motor Carrier Safety Regulation (FMCSR) 393.104, in addition to the corner irons and cables. The cargo securement system used must meet the general cargo securement requirements as listed under 49 CFR 393.100 – 393.114.

- The load should be checked after fifty miles of travel to ensure that it is still secure. If needed, the cables and cross ties should be tightened again to ensure that bins are still packed tightly together, as bins may shift during transit causing slack in the cables. Tightening the cables at this time is a very important step and must not be neglected. Additional checks should be made for longer trips as per 49 CFR 392.9.

- Posted speed limits should be strictly adhered to.

No special handling is required when using straddle trailers. Existing straddle platforms consist of steel tubing or wood timbers connected with four or five cross-members. The wood pallet of the 44 Series Hybrid bin enables it to be used on straddle platforms that have not been modified for traditional MacroBin use.

Pick-up Trucks and Small Trucks With Flatbeds

When transporting empty or full 44 Series Hybrid bins in a pick-up truck or small flatbed, the bin or bins must always be secured and covered to prevent loss of the bin or its contents. On flatbeds, bins must be strapped down as on larger flatbed trailers. After securing a bin, it should be checked to ensure it cannot move. In addition to securing the bin, it is also imperative that the tailgate be closed. If the truck does not contain hooks or cleats to secure a bin, or there is no tailgate in place, bins must not be transported in this truck. It is also essential that nothing is placed in the space between the bin and the tailgate. When transporting bins of differing heights, the taller bin should be secured against the cab, out of the wind stream, and the shorter bin should be placed toward the rear of the truck bed. The secured bin should be checked periodically to ensure that it continues to be secure for transport.

With their interlocking foot design, consistent dimensions, and dimensional stability over time, 44 Series Hybrid bins offer significant improvements over wood bins in space utilization and room filling efficiency. 44 Series Hybrid bins stack straight, reducing the space required between bins, and in many cases increasing storage volume significantly. Empty 44 Series Hybrid bins can be stored outside, as they are molded using a state-of-the-art UV stabilization system. Recommendations for the safe storage of full or empty bins are as follows:

- 44 Series Hybrid bins should always be stacked on hard level surfaces. When stacking more than four high, bins should only be stored in blocks of at least two stacks side by side. In general, the higher the stack, the wider the block. This will reduce the risk of bins being blown over by high winds.

- When 44 Series Hybrid bins are stored more than four high, they should be located in an area away from personnel activity. Unauthorized individuals should be kept away from bin stacks.

- Care should be exercised when de-stacking non-vented 44 Series Hybrid bins outdoors as the stack could be top heavy as a result of rainwater accumulation in the top bin.

Maximum Capacity and Stack Weight Limits

44 Series Hybrid bins have been designed to perform within specific maximum load capacities and stacking tolerances. For capacity and stack weight limits for 44 Series Hybrid bins, please refer to Macro Plastics product specification sheets.

It is essential to ensure that load stresses are transferred in the designed manner in a stack of bins. To achieve this, 44 Series Hybrid bins have been designed with an interlocking foot which ensures the proper bearing of loads.Under no circumstances should MacroBins be interstacked with wood bins or other manufacturer’splastic bins.Furthermore, the dimensions and interlocking systems differ between individual MacroBin models. 44 Series Hybrid bins must only be interstacked with other 44 Series Hybrid bins with an identical pallet base design.

Handling Equipment

The following rules should be followed when transporting empty bins on forklifts:

- Travel in reverse, as bins obstruct visibility in forward direction.

- Travel with forks tilted back, to prevent bins from sliding off forks in sudden stops.

- Make sure the forks are raised high enough to prevent the rear corners of the feet from dragging along the ground.

- Slow when cornering or driving over rough surfaces as empty bins may tip or bounce off of the forks.

- If the bins start to tip, quickly lower the forks so the feet contact the ground, stabilizing the stack.

- Never transport more than four bins high on a forklift.

- Maintain fork tips to ensure there are no large burrs or sharp edges as this will reduce damage to the radiused forklift entry area.

- When forklift rotators are used for dumping bins, rotator systems utilizing a clamp are recommended to prevent any movement of the bin when dumping.

Most bin trailers should require no modifications to handle 44 Series Hybrid bins. Modification is required when the top of the rollers are below the level of the top of the frame. This may cause the bin foot to rest on the frame instead of the rollers, thus preventing the bin from easily rolling off the trailer. In such cases, the rollers must be raised to a point where the top of the roller clears the top of the frame. This will allow the bin to roll freely. Depending on the height, the rollers must be raised. This can be done by either:

- Removing the rollers and adding a sleeve to increase the roller diameter.

- Re-drilling and raising each roller to clear the frame.

Most motorized bin carriers can handle 44 Series Hybrid bins with no modifications. The issue that may arise is the ability of the bin to travel in the recessed chain tracks. On some models, the path down the inside of this track is blocked by bolts or features along the frame preventing the bin from freely traveling on the chains as the inside edge of the foot impacts on the inside frame. On some models, bolts must be shortened to allow the bin to freely travel on the chains.

Packinghouse Equipment

44 Series Hybrid bins generally work very well with a vast majority of packinghouse dump lines. Their consistent dimensions result in higher bin throughput and increased productivity.

Most destacking equipment will handle 44 Series Hybrid bins with little or no modifications needed. It is also advisable to adjust the present guides, or to add guides, to insure that the 44 Series Hybrid bins is centered between the lifting dogs before being raised. The best way to test the compatibility of 44 Series Hybrid bins with your equipment is to fill some bins up with product and run them through the line.

No modifications to dumpers should be required when dumping 44 Series Hybrid bins.

As with destackers, most stacking equipment will run 44 Series Hybrid bins with little or no modifications. Running M44 Series Hybrid bins through the equipment will determine the compatibility of the bin with your equipment.

MacroBins have easily run through all floaters that they have been tested in. MacroBins have the added bonus of plastic construction allowing them to be immersed in water indefinitely without affecting the structural integrity of the bin.

MacroBins have been tested on many pre-size lines without issues. The dimensional stability and higher concentration of venting can result in smoother operation of filling lines.

Cleaning

Hybrid Bins can be cleaned using a high-pressure spray washer. High-pressure steam cleaners should never be used.

Maintenance

44 Series Hybrid bins component parts can be easily replaced if damaged. If the 44 Series plastic tub is damaged, it can be repaired using a hot air welding gun. See the User Guide section on hot air welding.

Recycling

If bins are damaged beyond repair, they can be recycled. Visit www.macroplastics.com/services/recycling/ to get information on how to recycle your worn out bins.